Manure Drying System (MDS)

Integrated MDS Drying System

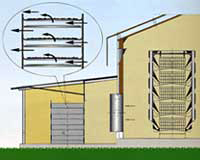

The MDS system has been designed to dry the manure produced in poultry installations by using the ventilation system of the installations themselves, which, if necessary, is integrated with independent fans. The MDS system cam be installed along side a shed predisposed for this aim or an alredy existing one, placed very close to the poultry installation. It is composed by a superimposed succession of motorised belts. Fresh manure is loaded onto the upper part and unloaded, to be transported to the stocking area, from the bottom level. The desiccation level of the final product, dry manure, allows an easy transportation and can be considered as an NP organic fertiliser, whose content of N and P2O5 is included on a range between 4 and 6%. Side picture: MDS system separately installed in a independent building.

Operation of the MDS System

MDS Manure Drying System

The MDS works in the following way: Starting the system the holed belts stay stopped until the manure, unloaded from the batteries, reaches, through the conveyors, the distributor. The weight of the accumulated manure on the distributor gives the signal to the MDS to start up through the sensor of minimum weight. In the moment in which the manure in the distributor begins to exceed, the maximum weight sensor stops the conveyors and the belts of the batteries up to that the excess is not distributed. Once the manure in excess is distributed on the holed belt the entire cycle starts again.

Perforated Belt Manure Distributor

The fresh manure is offloaded onto a distributor which spreads it uniformly onto the perforated belt. The perforation of the belts allow the air to go through the manure.

Detail of perforated belt to allow air passing through the manure. |

The number of tiers and their length is decided based on the number of birds in the shed. The manure is dried by the air coming from the shed. |

At the end of the process the dry manure is unloaded onto a cross belt. The duration of the drying process depends on the starting humidity of manure, on the humidity and volume of the air used and the frequency of the clearing operations. |

Advantages of the MDS system:

- Low costs for energy and no heating installations

- Drastic reduction of presence of ammonia (up to 95%)

- No need to dry the manure in the battery

- Low residual water contempt, up to a minimum of 15%

- Low costs for the installation

- Saleability of the final product thanks to a low weight and volume.