The vast range of solutions available grants the fulfillment of any type of layer production or density. The special design of the cage floor “soft balanced” which allows a very low egg breakage is one of Facco’s most appreciated features present in all layer cage configurations.

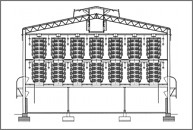

Pyramidal Type

A Frame 2 tier California model

Thanks to its design without any cage overlapping the California model is still considered an ideal solution for low density sheds with natural ventilation. The simplicity of its design and the high quality of the raw material utilized make it a battery cage of exceptional long life.

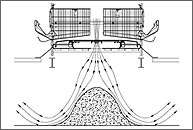

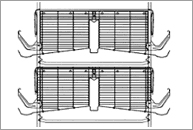

A Frame 2 To 6 Tier Nevada Model

A Frame 2 to 6 tiers Nevada model

Ideal for sheds with low medium density thanks to its design it ensures good light distribution amongst tiers and easy management. It is particularly suited for moderate climates and whenever a natural ventilation system is utilizable. Its versatility allows the use in high rise buildings or in shallow pit sheds with manure scrapers. It is equipped with rails proportionate to the number of tiers composing it to facilitate access to cage it allows inspection, even in the 6 tiers configuration, without the need for additional devices.

The typical manure deflector allows the complete protection of lower tiers preventing the manure falling into the cages and increasing hygienic standards and egg cleanness.

In high rise buildings configuration the cage can be complemented by a further manure removing tier to better control the air movement sending it directly onto the manure heaps underneath or alternatively it can be equipped with a manure belt for daily manure removal.

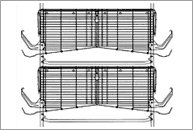

Manure Belt Type Standard

C3 Belt Type

With its first model introduced before the beginning of the ’70 he belt cleaning model best represents the constant improvement and innovation spirit which characterizes Facco’ products. This model nowadays called “C3 type” is definitely the most suited for the 21st century poultry production as it optimizes the ratio between density and shed’s volume thus best fulfilling the present days dimensional requirements. This typology is also suited for sheds where the manure can be removed periodically thus allowing a better control of the inside environmental conditions as it reduces the creation of flies. The simple installation required and lack of structural constrains makes it ideal for refurbishing of existing houses.

The “C3 type” is offered in 3 different models and various solutions to meet the most different needs and solutions:

The basic model without in cage manure drying facility is normally utilized in conjunction with an external manure drying system such as Facco’s MDS (see relevant information in the dedicated section). |

The solution with manure drying duct under the cage is ideal for moderate length sheds and allows to utilize the full cage depth. The special design with the duct all over the floor wire mesh grants a complete cleaning of the manure duct upper part done by the birds’ feet. |

The solution between the cages allows to reach up to 100 m length with one side only air blowing and 200 m with both sides air blowing. In this case the manure duct is also utilized as a drip saving device. |

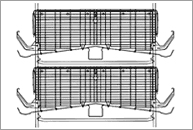

EU Standard Manure Belts

EU Standard Type

The EURO C3 is the new Facco’s cage for layers designed following the Eu Directive 1999/74/CE made by the European Parliament It comply with the criteria set therein:

- 750 cm2 per bird of which 600 utilizable space

- minimal height of the utilizable area 45 cm and 20 cm in the lowest point

- nest for egg deposition with non metallic floor

- 15 cm of perching spare per bird

- 12 cm of feeding space per bird

- adequate number of drinking system

- scratch area

- nail filing device

- 90 cm corridor between battery cages

- 35 cm minimum space between floor and 1st tier

Fully complying with the legislation Facco has created an innovative new type of battery cage already tested in several parts of Europe

First in this field Facco has identified the ideal cage size thanks to the long experience made in the Layer PS cages.

The Euro C3 is available in 3 different configurations: A) cm 120 front x 63,5 cm depth B) cm 240 front x 63,5cm depth C) cm 240 front x 127 cm depth The absence of any type of structural restriction allows the birds to roam freely and comfortably. |

Manure Scraper Type

Introduced in the early ’70s the Compatta battery cage is still the ideal design for high density sheds wherever it is possible to have a seasonal use of the manure which is kept in the lower part of the shed. The special care placed in designing the space between tiers and the heavy duty manure removing system, constantly improved over the years, allow to keep the manure onto the special belts on each tier for longer periods thus allowing a pre drying before conveying it to the lower storage area. This favors the creation of cones thus the optimal drying with little maintenance and great reliability.